供生物燃料规模化增产的可再生化学物

来源:《Science》

作者:S. Luterbacher等

时间:2014-03-20

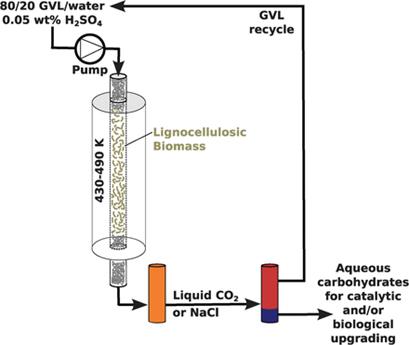

The flow-through reaction setup progressively dissolves biomass producing fractions that are rich in (from left to right) lignin monomers, hemicellulose and cellulose-derived sugars.

威斯康星大学麦迪逊分校的研究人员使用植物衍生化合物,研发了一个生产浓缩糖流的流程,其可以成熟应用于生物燃料。

由美国国家科学基金会和美国能源部大湖生物能源研究中心资助(GLBRC),该研究小组2014年1月17日在《科学》上发表了他们的发现,解释了他们使用γ-戊内酯(或GVL)降解植物生产糖的方式,这些糖可以通过化学或生物手段升级为生物燃料。受到威斯康星校友研究基金会的资助(WARF),该研究小组随后将开始扩大生产过程。

因为GVL源于植物材料,其既是可再生能源,又比需要昂贵化学药品或酶的转换方法更便宜。这个流程可以将85~95%的原料转化为糖,糖再用酵母发酵成乙醇,或化学手段升级呋喃产生生物燃料。(编译:中国科学院成都生物研究所 王芋华,王海燕)

Nonenzymatic Sugar Production from Biomass Using

Biomass-Derived -Valerolactone

Abstract Widespread production of biomass-derived fuels and chemicals will require cost-effective processes for breaking down cellulose and hemicellulose into their constituent sugars. Here, we report laboratory-scale production of soluble carbohydrates from corn stover, hardwood, and softwood at high yields (70 to 90%) in a solvent mixture of biomass-derived γ-valerolactone (GVL), water, and dilute acid (0.05 weight percent H2SO4). GVL promotes thermocatalytic saccharification through complete solubilization of the biomass, including the lignin fraction. The carbohydrates can be recovered and concentrated (up to 127 grams per liter) by extraction from GVL into an aqueous phase by addition of NaCl or liquid CO2. This strategy is well suited for catalytic upgrading to furans or fermentative upgrading to ethanol at high titers and near theoretical yield. We estimate through preliminary techno-economic modeling that the overall process could be cost-competitive for ethanol production, with biomass pretreatment followed by enzymatic hydrolysis.

原文链接:http://www.sciencemag.org/content/343/6168/277.full.pdf